In the industry of manufacturing of electric vehicles (EV), always in evolution, every decision counts. One of the most crucial elements in the production of high-quality electric vehicles is to guarantee the durability and reliability of vehicle batteries.

This is where Weibull comes into analysis as a powerful tool. We will demonstrate the four main uses of the Weibull analysis in the manufacture of EV batteries and how this tool can pay dividends in terms of economy of time and costs.

1. Optimized warranty processes

It is important to define adequate and realistic guarantee policies to balance customer expectations and financial sustainability. Weibull can help manufacturers estimate battery life distribution, which will allow them to create generous and fiscally responsible guarantees.

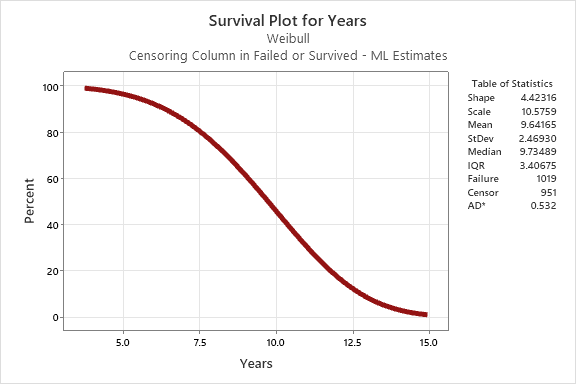

We show here data from more than 10,000 batteries. As you can see, most 95% batteries last 5 years, with an average useful life of just under ten years. This information can help electric vehicle companies make smarter, more informed decisions.

2. Wonderful product quality

Battery manufacturers must continually strive to improve the quality and reliability of their products to meet the demanding requirements of the electric vehicle market. This includes identifying and resolving possible project defects, material weaknesses or manufacturing process problems that may lead to deterioration or premature battery failure.

For example, you may be analyzing field data and identify that a particular battery model has a higher rate of failure than expected due to overcharging during rapid charging. A Weibull can be used to identify the fault mode and work correctly in the battery thermal management system, improving the quality and reliability of the product.

3. Reduce manufacturing costs

Weibull helps reduce waste and guide production processes that can reduce costs. It can also help identify where resources can be used most efficiently.

A Weibull analysis can reveal that a specific production stage, such as the electrolyte storage process, contributes to variations in the useful life of the battery. The analysis provides information on the distribution of the useful life of the batteries, revealing that inconsistencies in the electrolyte filling process can lead to a greater probability of early failures.

4. Allocation of resources

Weibull can help prioritize which batteries or batches of products require closer monitoring or more in-depth investigation, or allow for greater allocation of resources.

For example, in a factory, Weibull analysis can help identify that a particular production line produces batteries with a shorter useful life. The manufacturer can allocate more people and quality control resources for this line to solve the problems or as quickly as possible and reduce possible defects.

Content removed from the official channel of Minitab.

Source: www.minitab.com.br

Talk to me Software.com.br and know better or Minitab together with a specialist.

3 min reading

3 min reading